Garbage In, Garbage Out: How Sensor Accuracy Impacts AI-Driven Precision Ag

Accurate sensor data is the backbone of effective AI-driven precision agriculture. The 'garbage in, garbage out' (GIGO) principle underscores that poor data quality leads to poor model performance, impacting all precision ag modeling efforts. We'll illustrate this concept using precision irrigation as a key example.

Precision irrigation aims to optimize water use by precisely matching irrigation to crop needs, where soil moisture sensors play a crucial role in providing data that informs irrigation decisions. But what happens when the data you're feeding into your system is inaccurate? That's where the concept of 'garbage in, garbage out' (GIGO) becomes particularly relevant.

Let's illustrate this using a simplified example: linear regression.

Linear Regression: A Basic Tool for Prediction (and Why Garbage-Out is Inevitable)

Linear regression is a straightforward statistical method used to model the relationship between two variables. In our case, we might use it to predict soil moisture content based on sensor readings. For instance, we could try to predict volumetric water content (VWC) based on the raw voltage output of a soil moisture sensor.

The general form of a linear regression equation is:

y = mx + bWhere:

y is the predicted VWC (e.g., in %).

x is the raw sensor reading (e.g., voltage in mV).

m is the slope of the line.

b is the y-intercept.

Why Linear Regression Struggles with "Garbage-In":

Linear regression attempts to find the "best-fit" line through a set of data points. If the data points are scattered randomly due to sensor noise and inaccuracies (as with low-quality sensors), there's no meaningful relationship to model. The resulting line will be a poor representation of the actual relationship, leading to inaccurate predictions.

Example: High-Quality Sensor Data (Good Input = Good Output)

Let's say we have a high-quality sensor. After calibration and testing, we obtain the following data:

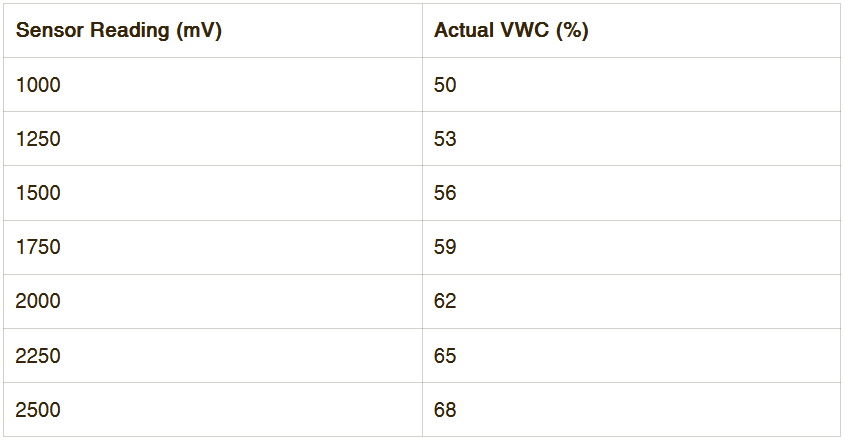

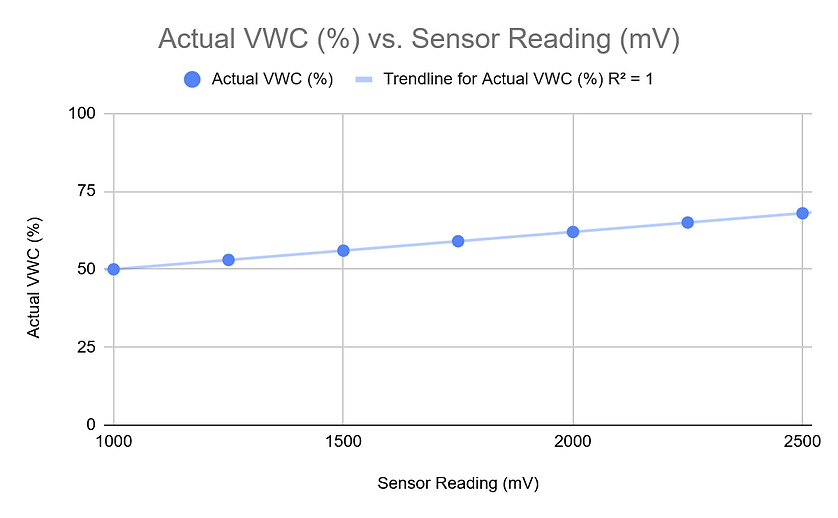

Table 1: High-Quality Sensor Data

After performing linear regression, we might get an equation like:

VWC = 0.012 × SensorReading + 38For a 1750mV reading, we predict a VWC of 59%. The R-squared value for this regression is 0.99, and the p-value is extremely low, indicating a strong fit.

Example: Low-Quality Sensor Data (Bad Input = Bad Output)

Now, imagine we're using a low-quality soil moisture sensor that provides inconsistent and inaccurate readings. Our collected data will be noisy and unreliable.

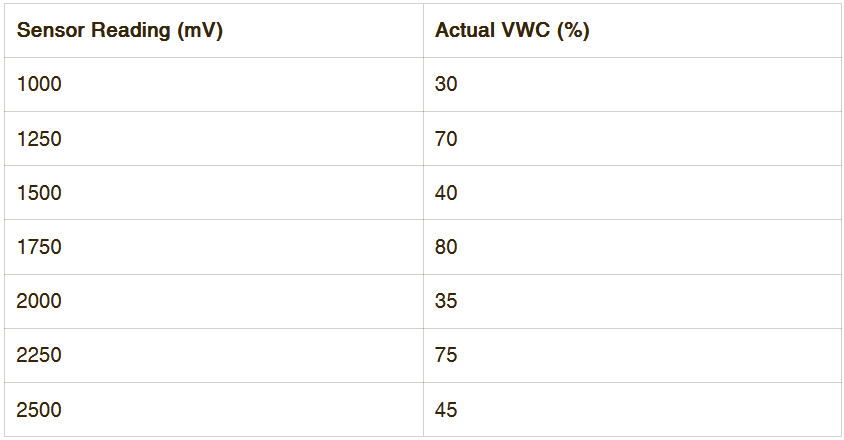

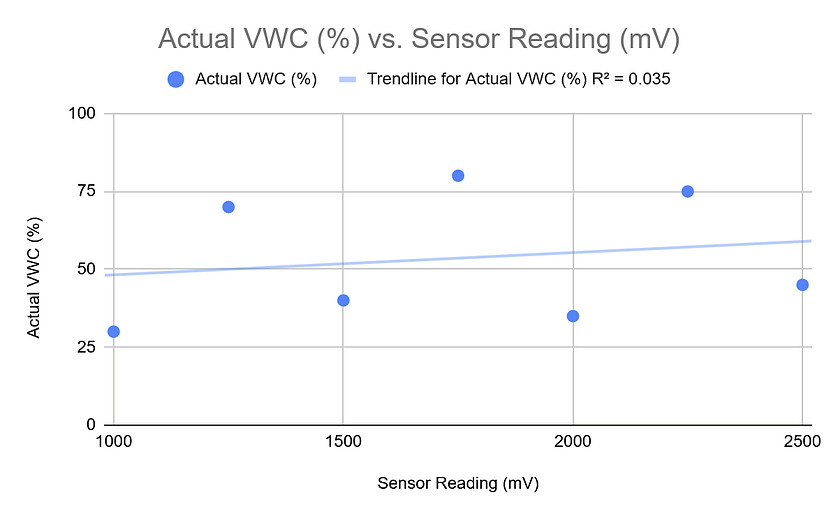

Table 2: Low-Quality Sensor Data

When we perform linear regression on this "garbage" data, we might get an equation like:

VWC = 0.00714 × SensorReading + 41.1The R-squared value for this regression is approximately 0.035, which confirms a very weak linear relationship (if any) between the sensor readings and the actual VWC, as expected from low-quality, noisy data.

Beyond Linear Regression: The GIGO Principle Extends to All AI Models

While linear regression is a simple example, the "garbage-in, garbage-out" principle applies to all machine learning and deep learning models. No matter how sophisticated your AI algorithm is, it cannot magically extract meaningful patterns from fundamentally flawed data.

Complex Models, Same Problem: Advanced models like neural networks or support vector machines can handle more complex relationships, but they still rely on the input data's quality. If the input data is noisy and inconsistent, the model will learn those inconsistencies, leading to inaccurate predictions.

Wasted Time and Resources: Trying to build complex AI models with low-quality sensor data is a waste of time and resources. You'll spend significant effort training a model that ultimately produces unreliable results.

Focus on Data Quality First: The most effective approach is to prioritize data quality. Invest in high-quality sensors, ensure proper calibration, and implement data cleaning and preprocessing techniques. This will provide a solid foundation for any AI model you build.

Sensor Quality Matters

Extremely Low-Quality Sensors: Some very cheap sensors, like those found online for a few dollars, can have errors exceeding 100%, and may not even provide consistent measurements. This level of inaccuracy makes them completely unsuitable for precision irrigation.

High-Quality Sensor Limitations: Even the best soil moisture sensors face challenges. Soil and substrate variability, such as differences in texture, compaction, and salinity, can introduce significant errors. In substrates like coco coir, which expand and contract, errors can easily exceed 50%. Therefore, even high quality sensors, can easily have errors of 10% or more.

Mitigation Strategies: To address these challenges, strategies like using multiple sensors and averaging their readings can help reduce variability. While averaging can improve accuracy, reliable sensors remain essential for a solid foundation. For more in-depth guidance on improving sensor data quality, including calibration techniques and best practices, please refer to my other articles and posts on Professor Balthazar's Substack and the EnviTronics Lab Blog.

Real world scenario:

Consider a crop that thrives with soil moisture maintained around 40% VWC for optimal growth. Sensor inaccuracies can lead to significant irrigation errors, impacting crop health and water usage. This impact is magnified when automated irrigation systems or expert systems rely on faulty sensor data, as they lack the farmer's visual cues and contextual understanding.

High-Quality Sensor:

Measures 44% VWC (within a 10% error margin).

Whether interpreted by a farmer or an automated system, the correct action is to withhold irrigation, allowing the soil to dry naturally to the target level.

Low-Quality Sensor (High Reading Error):

Measures 52% VWC (within a 30% error margin).

A farmer might notice slight signs of dryness in the field and override the sensor's reading. However, an automated system will likely under-irrigate or completely withhold irrigation when irrigation is actually needed, potentially leading to water stress for the crop.

Low-Quality Sensor (Low Reading Error):

Measures 30% VWC (within a 30% error margin).

A farmer might observe that the field isn't excessively dry and adjust accordingly. But an automated system will likely over-irrigate, potentially leading to waterlogging and root damage.

Very Low-Quality Sensor (Extreme Error):

Measures 60% or 20% VWC (within a 50% error margin).

Whether a farmer or an automated system is using the data, the resulting irrigation decisions will be drastically incorrect, leading to severe over- or under-watering.

Averaging Several High-Quality Sensors:

Provides a more stable and accurate representation of soil moisture, reducing the impact of individual sensor variability and improving irrigation precision. This is particularly crucial for automated systems, which rely solely on sensor data.

Calibration and Accuracy

To ensure accurate data, sensor calibration is often necessary. Understanding sensor accuracy, precision, and resolution is key to making informed decisions. To gain a deeper understanding of these concepts and the importance of sensor calibration, I encourage you to read this article: "Do I Need to Calibrate My Sensor Before Using?"

Summary

In summary, the accuracy of precision irrigation hinges on sensor quality. Inaccurate data, or "garbage in," inevitably leads to unreliable results, or "garbage out," regardless of the sophistication of the irrigation system or AI models employed. Investing in reliable sensors, proper calibration, and data preprocessing is crucial.

High-quality data ensures informed irrigation decisions, optimizes water use, and ultimately benefits crop health and resource conservation. Prioritizing sensor quality is therefore essential for effective and sustainable agricultural practices.

Comments

Post a Comment